The vacuum belt filter is used for the filtration of liquids and dewatering of sludges.

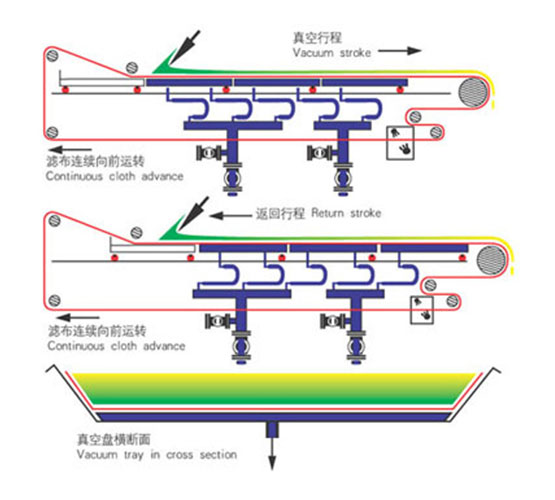

Unlike hydrostatically working filters, the filtration is made by gravity with an additional vacuum support. As a result, higher throughputs and better dewatering of the filter cake can be achieved. Depending on the application, filter fleeces or endless filter belts are used.

In many applications, the vacuum belt filter provides an effective alternative to belt filter presses or chamber filter presses as well as centrifuges.

Sefar filter belt solutions for Vacuum Belt Filters

Choose Sefar as your trusted source for filtration. We are ready and capable to meet your needs. Understanding the filtration process is one key requirement for filter solution development. This is a Sefar core competence. We have spent decades developing filter media made from synthetic yarns. Sefar’s innovative synthetic fabrics are the material of choice for horizontal vacuum belt filters. Sefar filter belt solution offers excellent separation efficiency and a long, trouble-free lifetime.

1. Circular rubber belt adopts the adhesive structure of wave-shaped skirt brim and flat rubber belt with excellent flexibility. It has a low cost and long life. And also the skirt brim can be replaced.

2. There is a circular friction belt between the vacuum chamber and rubber belt that is sealed, lubricated and cooled with water. The vacuum sealing is dependable. The circular friction belt has small friction resistance, long service life and is convenient and swift to replace.

3. Rubber belt adopts airbag or water film supporting. The rubber belt floats on airbag or water film, reducing moving resistance and good for prolonging the service life of rubber belt.

4. Rubber belt supports filter fabrics, takes vacuum pumping power conveys power efficiency and takes the weight. It also slides on a vacuum chamber. Filter fabrics do not contact the vacuum chamber and have a longer service life.

5. It realizes continuous operation, filtering and rinsing etc. It can maintain a stable vacuum, the lower water content of filter cake and is good for stabilizing operational technical conditions.

6. There are fewer perishable parts, lower malfunction ratio longer reliable continuous running term and the larger amount of materials to deal with.

7. Fitting belts to the specific filter equipment is essential for smooth and efficient filtration performance.

8. The market-leading expertise of Sefar helps to define the most suitable filter media and fabrication method for your application. With Sefar's unique belt design you can count on consistent performance.

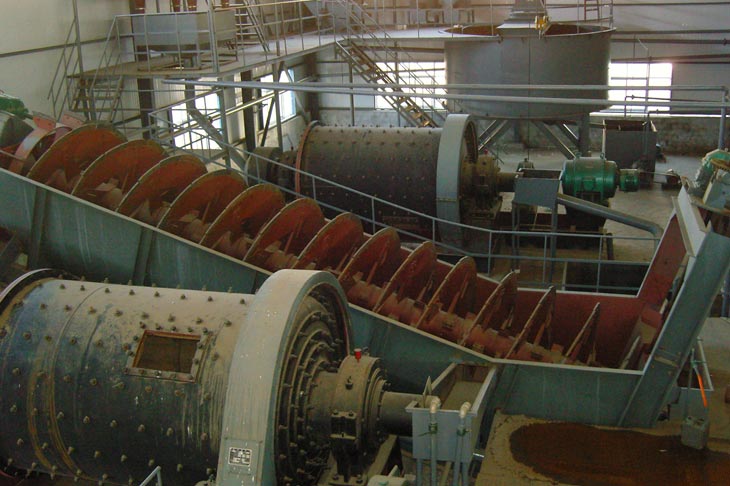

Filter plate immersed in the pulp while in operation produces a surface absorption of filter cake, with the action of capillarity and integrated with vacuum pressure. Filtrate enters the distributing valve and drainage tank through the filter plate. Filter cake comes out from slime hopper receiving spray washing. Filter cake falls into the tank by the pressure from the wind and scraper.

It can be used for floating and dewatering in clean coal and fine materials like tailings, and it can be also used in metallurgy, chemical, petroleum, sewage treatment, and other aspects of the solid-liquid separation.